-

Our History

Over the past 20+ years, Wet Tech has had to adapt and evolve to the cycles of the oilfield and expand our products and services to cater to many other industries that we can serve with the same dedicated service. Family owned and operated since day number 1, we remain committed to not only our global clients and customers, but also to the local suppliers, vendors and people in our area.

1999

1999

Wet Tech was incorporated in August 1999 as a small family owned and operated service company in south Louisiana. Our focus was offshore navigation aid system inspections and project management services

2002

2002

Wet Tech successfully performed its first buoy deployment

2004

2004

Wet Tech manufactured and deployed more than 50 buoys offshore

A contract with Noble Energy was awarded to Wet Tech for their Main Pass Hurricane Ivan Salvage project

Wet Tech provided the preset mooring systems for the Crowley CMC450 barge in the Main Pass field starting a pathway for our successful mooring division.

2008

2008

By 2008, Wet Tech was the leading buoy company with well over 300 buoys manufactured, deployed and maintained with over 40 unique offshore oil companies.

2009

2009

Wet Tech executed a joint master service contract with Versabar along with Chevron, Noble Energy, BP, Taylor Energy, Anadarko and Shell all combined into a single contract which was a first of its kind.

Provided preset mooring systems and offshore services for mooring installation, recovery and reset at over 60 project locations for a combined group of oil companies, Wet Tech performed all work with zero incidents or injuries.

2010

2010

Wet Tech was contracted directly with BP to provide labor and equipment for the oil spill response for the MC 252 Macondo Oil Spill which we performed without incident until the oil spill was deemed to be cleaned up in 2012.

2011

2011

Wet Tech purchased a 180’ Offshore Supply Vessel and retrofitted it to become a custom Anchor Handling/Buoy Tender vessel for serving our 100 unique clients and customers.

2013

2013

Started providing preset anchor systems and buoys for the largest lift system in the USA, Versabar’s VB10,000 until it became USCG certified Dynamic Positioned in 2014.

Wet Tech had over 200 buoys offshore that were maintained and inspected per USCG and MMS (BSEE) regulations.

Oil prices began to fall to all time low levels creating a very challenging marketplace. We started to look for other industries to enter and today, we are excited that we did so.

2015

2015

Wet Tech was initiated by NOAA through Prime Contractor, SAIC to integrate and complete the 6-Meter Nomad weather buoys. We also started working directly for the US Navy fabricating and delivering their subsea target buoys

2017

2017

We were awarded a multi-million dollar fabrication/delivery contract for the USACE, through Kiewit Infrastructure for the McCook Reservoir in Chicago, IL

2018

2018

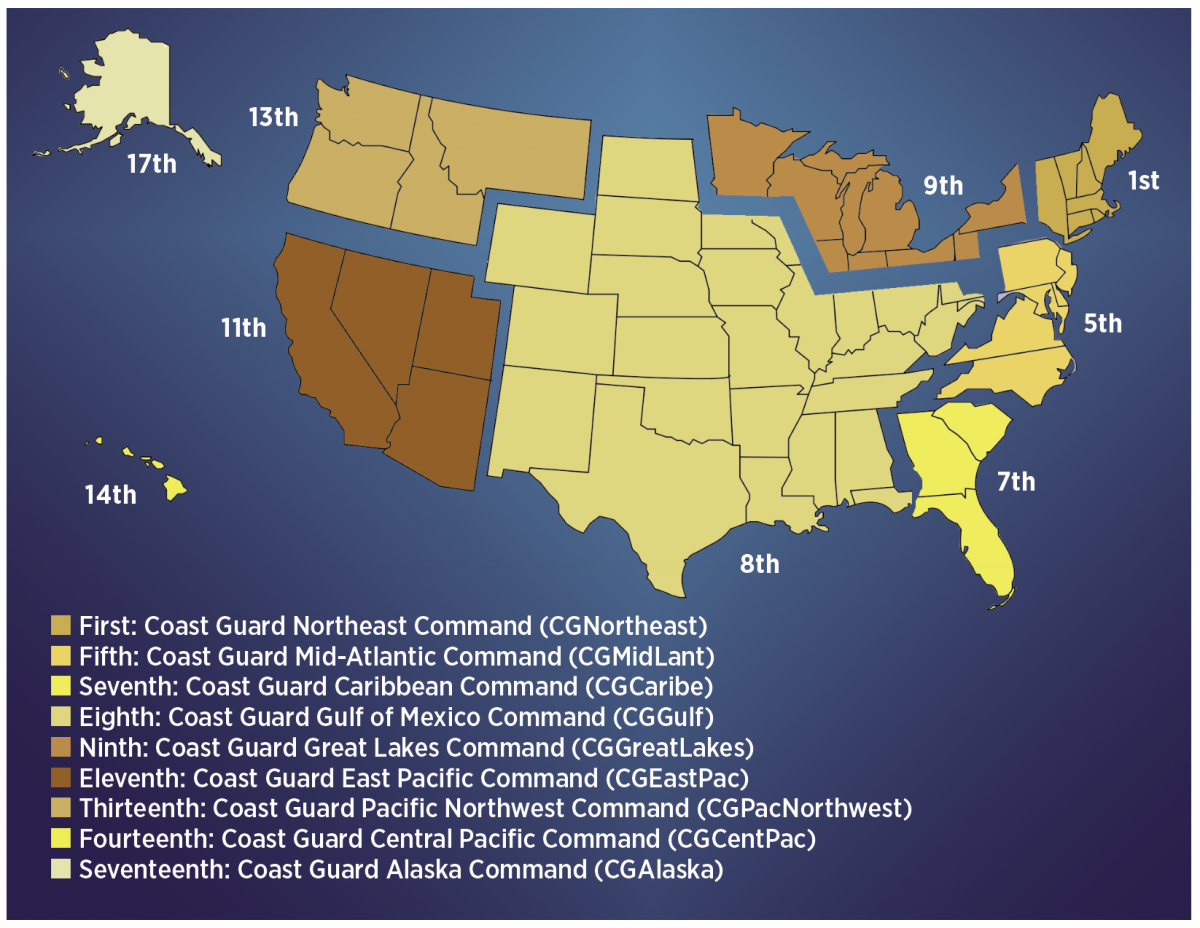

In 2018, Wet Tech responded to a Request for Information from the USCG for a buoy maintenance/overhaul opportunity. After government shutdowns and competitive contract negotiations, in 2019 we were formally awarded the contract for the USCG for districts 1,5 and 11. After a very successful first year of USCG contract performance, Wet Tech was asked to modify the existing contract to include additional districts 7, 8 and 9.

2019

2019

We entered the mariculture industry by partnering with Forever Oceans, a company involved with offshore automated fish farming in Panama, Hawaii and soon to be in South America with providing them large buoyancy modules for their offshore fish farm cage systems.

2020

2020

Okaloosa County awarded our company the contract for provision of 4 FAD (Fish Aggregating Device) buoys to be fabricated and installed offshore. They will provide real time weather data 60-80 miles offshore Destin, Florida. They were Deployed in early November.

2020

2020

Wet Tech also has provided all preset mooring systems for the overturned car carrier, M/V Golden Ray in St. Simon’s Sound out of Brunswick, GA for T&T Salvage, Versabar and the Unified Command currently now in progress since originally commencing in March 2020 and paused for COVID and hurricane season.